Industrial panel monitors are widely used in manufacturing, logistics, medical, transportation and other industrial fields to improve the efficiency and accuracy of information transmission. Industrial panel monitors have a durable structure and generally adopt an all-steel design. The panels of industrial panel monitors are divided into ordinary iron plates, stainless iron, stainless steel, aluminum panels and other different materials with special designs of dustproof and shockproof. Industrial panel monitors will use industrial-grade wide temperature (-40 to 85 degrees) LCD screens when the environmental requirements are high. The wide temperature support of industrial panel monitors is an important feature of its adaptation to extreme environmental conditions. Industrial panel monitors are usually designed with a wider operating temperature range, such as -20°C to 70°C, to meet the needs of different industrial environments. In addition to the operating temperature range, industrial panel monitors also have a wider storage temperature range, usually from -40°C to 85°C, to ensure safe storage when not in use.

The AR anti-reflective coating of industrial panel monitor can reduce the reflection of external light sources on the display screen, enhancing the readability of the industrial panel monitor display content, especially in strong light environments. industrial panel mount touch screen monitor It allows the display to fit tightly against the wall or control panel, suitable for industrial environments with limited space. And the touch screen monitor is directly mounted on the panel to provide a stable support for the display, reducing the impact of movement or vibration on the industrial panel monitor.

industrial panel mount touch screen monitor

industrial panel monitor It meets the panel installation standards, which allows the display to be easily integrated into various industrial control panels or operating tables. The industrial panel installation design saves space for the touch screen monitor. Allowing the industrial panel monitor to fit tightly against the wall or control panel, it is suitable for industrial environments with limited space. The industrial panel mount touch screen monitor can provide stable support and reduce the impact of movement or vibration on the industrial panel monitor.

industrial panel monitor industrial-grade LCD display

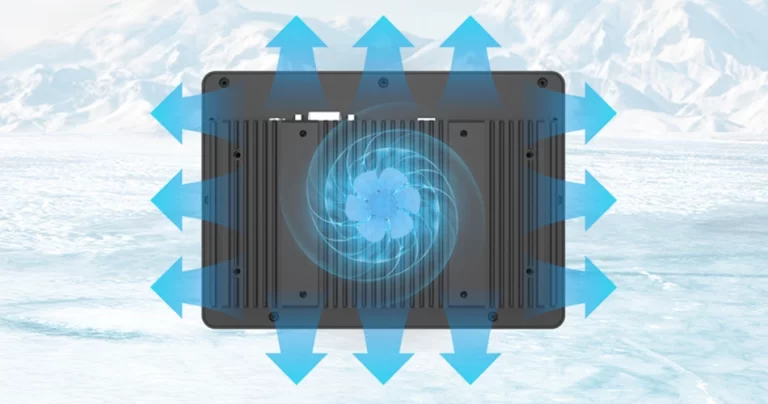

The temperature support of industrial panel monitor is key to ensuring that the device can work properly in extreme temperatures. When industrial panel monitor is facing high and low temperature working environments, special technologies are required to ensure its normal operation. 1. Use low-temperature heating to heat point by point or the entire surface to increase the overall power consumption of industrial panel monitors to ensure normal operation in low-temperature environments (such as -40°C). 2. Improve the brightness of industrial panel monitor LCD screens. Use a high starting voltage generated by a special high-voltage bar to light up the backlight tube in a low-temperature environment, and use the heat generated by the tube to heat up the liquid crystal, while solving the problem of industrial panel monitors working at low temperatures and being visible in the sun.

Industrial panel monitors do not rely on heating or brightening. They use software to correct the drift of electrical characteristics at low temperatures, adjust the driving timing of the liquid crystal, etc., to ensure that the liquid crystal works normally in a wide temperature environment. Choose a wide-temperature industrial panel monitor LCD screen: A wide-temperature industrial panel monitor LCD screen has better temperature adaptability and can work normally in a wider temperature range. This type of industrial panel monitor LCD screen uses special liquid crystal materials and designs to maintain good display effects in low-temperature environments. Liquid crystal itself changes its physical properties at different temperatures. Industrial panel monitors use specially formulated liquid crystal materials to ensure that display performance is maintained over a wide temperature range.

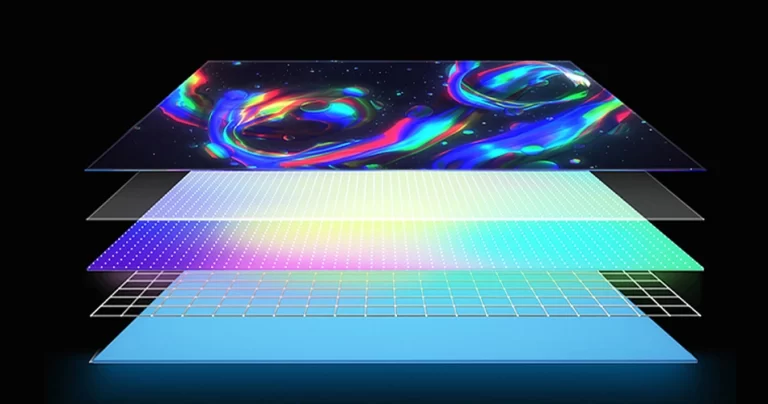

AR coating for industrial panel monitors

AR coating for industrial panel monitors is a special surface treatment technology for anti-reflection. The purpose of applying AR coating on the surface of industrial panel monitors is to reduce the reflection of external light sources on the industrial panel monitor screen, so as to enhance the readability of the content displayed on the industrial panel monitor, especially in strong light environments. AR coating for industrial panel monitors can refract and disperse incident light through a chemical etching process to achieve an anti-glare effect. In order to improve the anti-reflection of industrial panel monitors, AR coatings usually use a multilayer film structure consisting of a high refractive index layer and a low refractive index layer. Since the AR coating is installed on the outermost surface of the industrial panel monitor, the coating is required to have high scratch resistance and high mechanical strength and be able to adhere well to the underlying layer. Go to panel PC manufacturer home page.