touch monitor industrial uses durable and high-quality materials and construction. It uses a high-resolution LCD panel to provide clear images and good color performance. The design of the touch monitor industrial takes into account the chemicals and electromagnetic interference that may exist in the industrial environment. Therefore, corrosion resistance and electromagnetic interference resistance are essential for the touch monitor industrial. The use of corrosion-resistant materials such as stainless steel or special coatings on the touch monitor industrial housing and components to resist the erosion of chemicals and EMI shielding materials and designs can reduce the impact of electromagnetic interference on the monitor’s performance. And the good grounding design of the touch monitor industrial helps to guide the electromagnetic interference to the ground and protect the monitor from damage.

EMI (Electronic Interference) Shielded Touch Monitor for Industrial Use Touch Monitor

Electromagnetic interference (EMI) shielding of touch monitor for industrial use is the key to ensure the stable operation of the touch monitor industrial in complex electronic environments. Special EMI shielding materials for touch monitor industrial such as; special materials provided by Henkel, these touch monitor industrial materials are designed for package-level electromagnetic interference shielding. With excellent performance and characteristics, it can provide reliable shielding and bonding performance and perform well in stressful electronic conditions and environments. Touch monitor for industrial use Using Henkel’s flexible material formulation not only means higher reliability and more powerful functions, but also ensures a more scalable process, higher production volume and lower implementation cost of touch monitor industrial EMI shielding solutions in touch monitor industrial innovation.

Coatings for touch monitor industrial

The use of special coatings for touch monitor industrial can improve the display effect of touch monitor industrial and enhance the durability and protection of touch monitor industrial screens. There are many types of coatings used for touch monitor industrial, such as; Optical bonding coating: This coating can improve the impact resistance of touch monitor industrial touch screens and reduce light reflection, especially suitable for outdoor use or industrial environments that require increased security and debris protection.

Anti-fingerprint coating; touch monitor industrial’s anti-fingerprint coating helps keep touch monitor industrial screens clean, reduce the impact of fingerprints and oil stains, and improve the user experience. Anti-bacterial coating; touch monitor industrial’s anti-bacterial coating helps reduce the accumulation of static electricity, thereby reducing the attraction of dust and other particles to the screen. Hard coating: The screen glass of the touch monitor industrial is treated with a hard coating to improve the scratch and wear resistance of the touch monitor industrial screen. Anti-glare coating: The touch monitor industrial uses this coating to reduce screen reflection and glare, improving visibility in strong light environments.

best touch monitor industrial

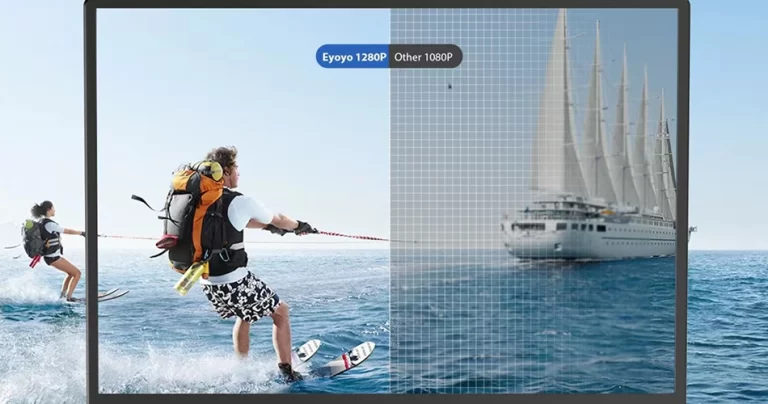

The personalization of the touch monitor industrial can customize the features and functions of the best touch monitor industrial according to the needs of specific industrial applications. We can provide users with resolutions and display technologies that are suitable for application requirements. And customized connection requirements include multiple interfaces such as USB, HDMI, DVI, DisplayPort, etc. Provide customized touch monitor industrial appearance, front panel and frame color and material selection to match the brand or machine design best touch monitor industrial, etc. If you have any needs, please contact china monitor factory.